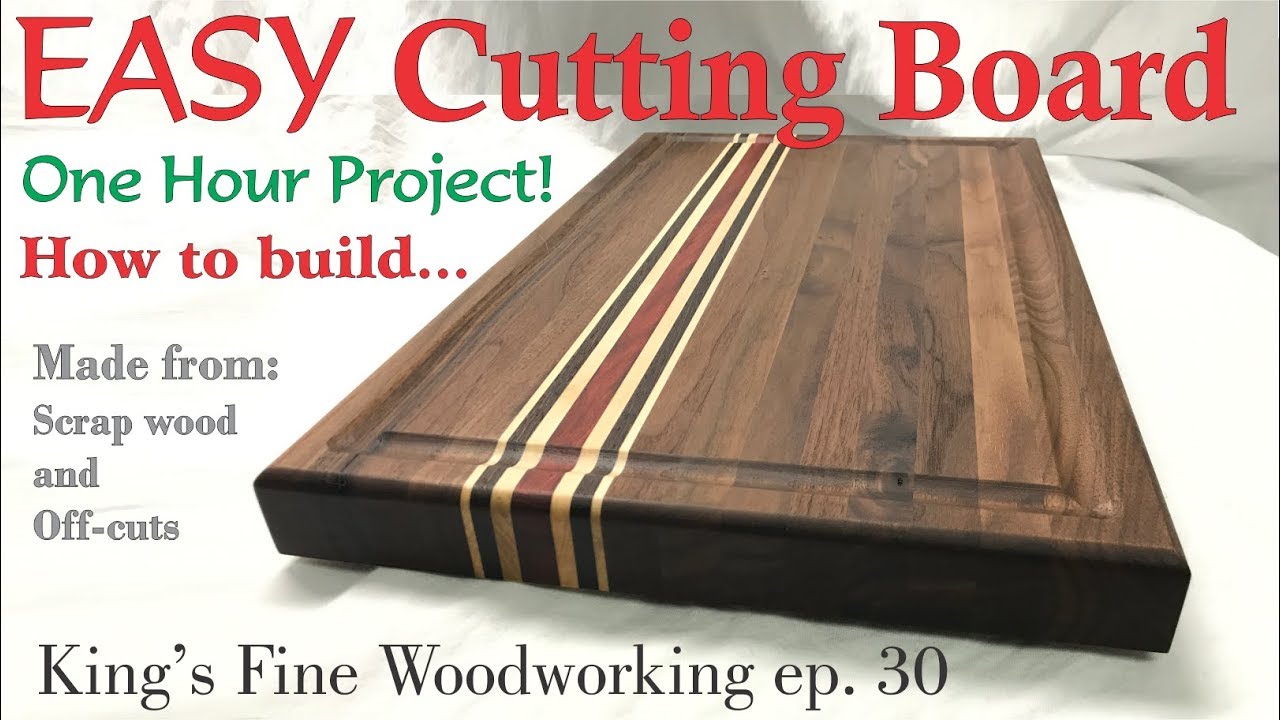

how to make end grain cutting board video

Maple and walnut end grain cutting board. I scrape the dried glue from each side of the cutting board and then a few light.

When the glue is dry in an hour or so clamp a stop to the miter-saw table 2 inches from the blade.

. In this video Im showing you the process of making a walnut end grain cutting boarda timeless classic I make again and again. Complete construction diagrams and cut list are included in the video. I simply used food grade mineral oil for the first step and the a mix of mineral oil and wax for the.

Hi In this woodworking video I take you through the process on how to create an awesome 3D end grain cutting board. For a regular end. Next glue them together and.

I milled the walnut to a little over 34 thick and cut it to. The tools you will need for this project are a circular saw table saw joi. Shift each one sideways so that the glue joints in each strip are offset from the ones in the neighboring strips.

Dont over tighten the clamps but you do want to see some glue squeeze out. First cut strips from both types of wood should vary in thickness. Apply Oil and Wax.

Here you need two types of wood like light wood and dark wood to make this cutting board. The Initial Glue Up. The number of materials you will use depends solely on your desired size of the board.

The Making of a Walnut End Grain Cutting Board. End grain cutting board is treated with food grade. Learn how to get started woodworking and set up shop for less than 1000.

In this how-to woodworking video woodworker and author Paul Mayer walks you through all the steps to. I milled the sapele and maple to a bit over 12 thick and cut the boards into strips slightly wider than 1. In this excerpt from The Wood Whisperer video podcast woodworker Marc Spagnuolo walks viewers through the process of making an end-grain cutting board from.

This cutting board is inspired by one c. Its fun its easy so give it a try. So your end grain board is all laid out lets get to gluing.

It is waterproof and food safe. As mentioned I only use Titebond III in my cutting board construction. Start by using masking tape and CA glue to create a straight edge on one of the long edges as shown.

Today I will be showing you how to build an end grain cutting board with red oak. Use the same gluing technique as. So cross-cutting a 6 wide board.

This step also has a wide range of options. Place all the strips so the end grain faces up. I scrape the dried glue from each side of the cutting board and then a few light passes thru the.

I made this end grain cutting board from hard maple and sipo sipo is an African wood also known as utileAn end grain cutting board is the preference of ch. In this video I show you how you can make your own end grain cutting board that will stand out from the crowd. Finger Grips cut outs on both sides.

Nonslip rubber feet fixed with stainless steel screws. To make an end grain cutting board you do not need many materials. The general rule about cross-cutting end-grain against the fence stems primarily from the fact that most lumber is much longer than it is wide.

Now clean up all 4 sides of the board. Then clean up the other.

Pin On Woodwork I Would Like To Do

How To Make A Endgrain Tumbling Block Butcher Block Board By Degoose Lumberjocks Com Woodworki Woodworking Projects Diy Woodworking Projects Wood Crafts